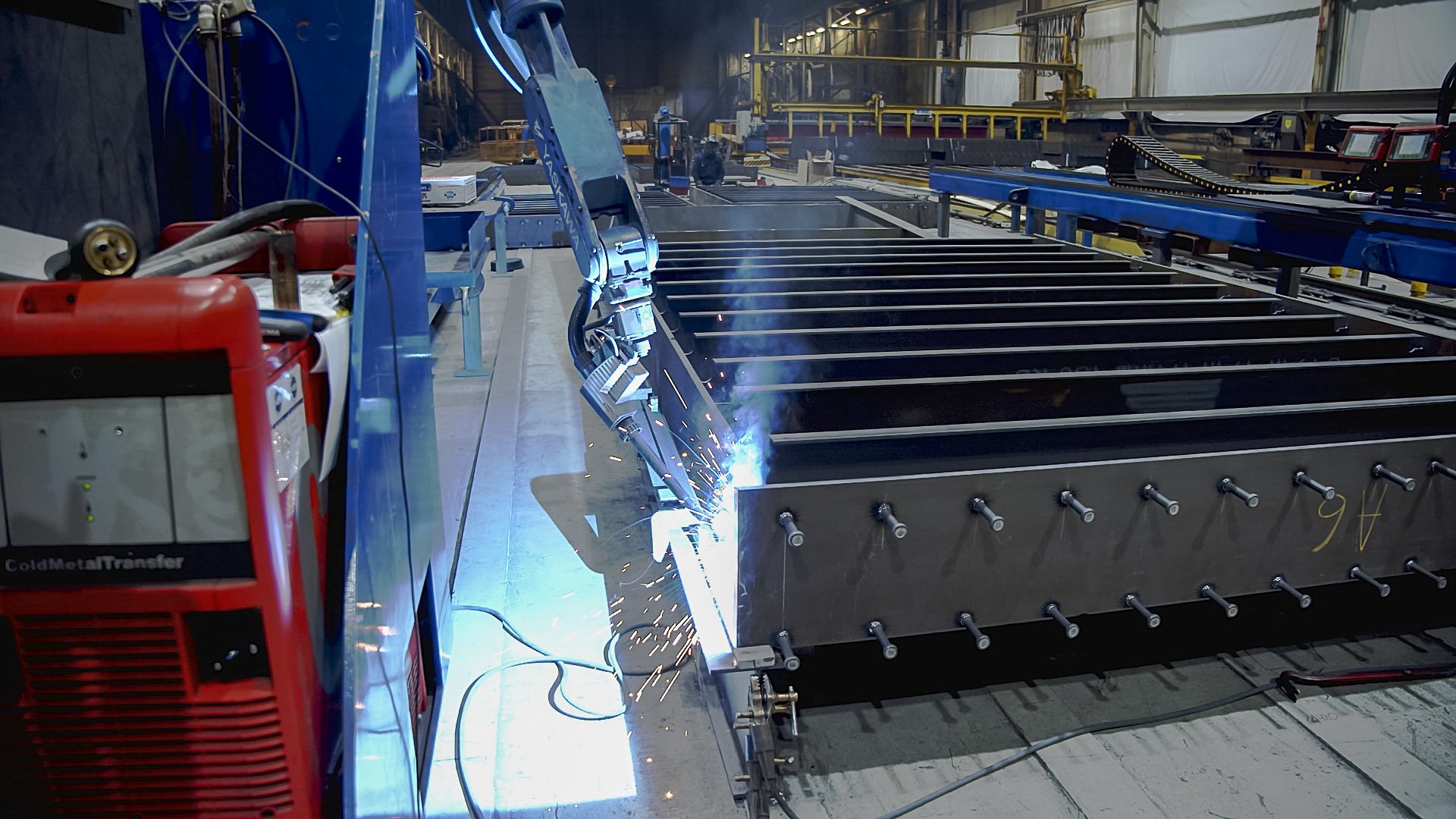

Welding

Robotic welding is one of our core specialties. Taking advantage of modern technology, automated welding processes has proven its capabilities by delivering top quality results. By including multiple welding technologies, we are able to implement efficient production methods on a large variety of manufacturable products.

Laser-hybrid

This technology combines features from laser and traditional MIG/MAG. The laser heats material to the melting point and welding wire is applied to the welding pool. This method produces a weld seam with the characteristics of a traditional seam with the low heat input and high travel speed of the laser. This results in a precise seam, applied at high speed along with a low level of deformation. In many cases the laser-hybrid seam does not require any kind of finishing touch up work.

Laser

Laser welding methods result in deep and accurate welds that require less energy and resources compared to traditional welding methods. Laser welding is also applying less heat to the material due to a small HAZ (Heat Affected Zone). It produces a clean seam that often does not require any form of finishing work. This is a method that is very suitable for robotic handling due to the precision required for acceptable results.

The process of laser welding consists of a focused laser beam which heats the work piece material to melting temperature. The seam is created by the motion of the focused beam along the workpiece. Approximately 1 kW output power per 1,5 mm sheet thickness is required for a fully penetrated weld.

GMAW (MIG/MAG)

Gas metal arc welding is a traditional method of electric arc welding which consists of an arc created between a consumable metal electrode (welding wire) and the work piece. Gas is used to shield the welding pool from external gases such as nitrogen and oxygen, to prevent unwanted chemical reactions.

This is a well proven and versatile welding technology that can be applied in most welding scenarios. This welding method is also adaptable to automated applications. In most cases robotic handling provides both more precise and efficient production output compared to manual handling.