Micro Panel Line

A high-capacity robotic welding line designed for efficient production of bulkheads, beams, and webs. With dual welding tables and two industrial robots, the system ensures continuous operation and excellent weld quality.

Dual Welding Positions

While one table is in the welding zone, the other is being set up — allowing seamless transitions between tasks and maximizing overall productivity.

Two Robots with Offline Programming

Robots are programmed offline using a digital twin of the robot cell, enabling fast setup, simulation, and optimization without interrupting production.

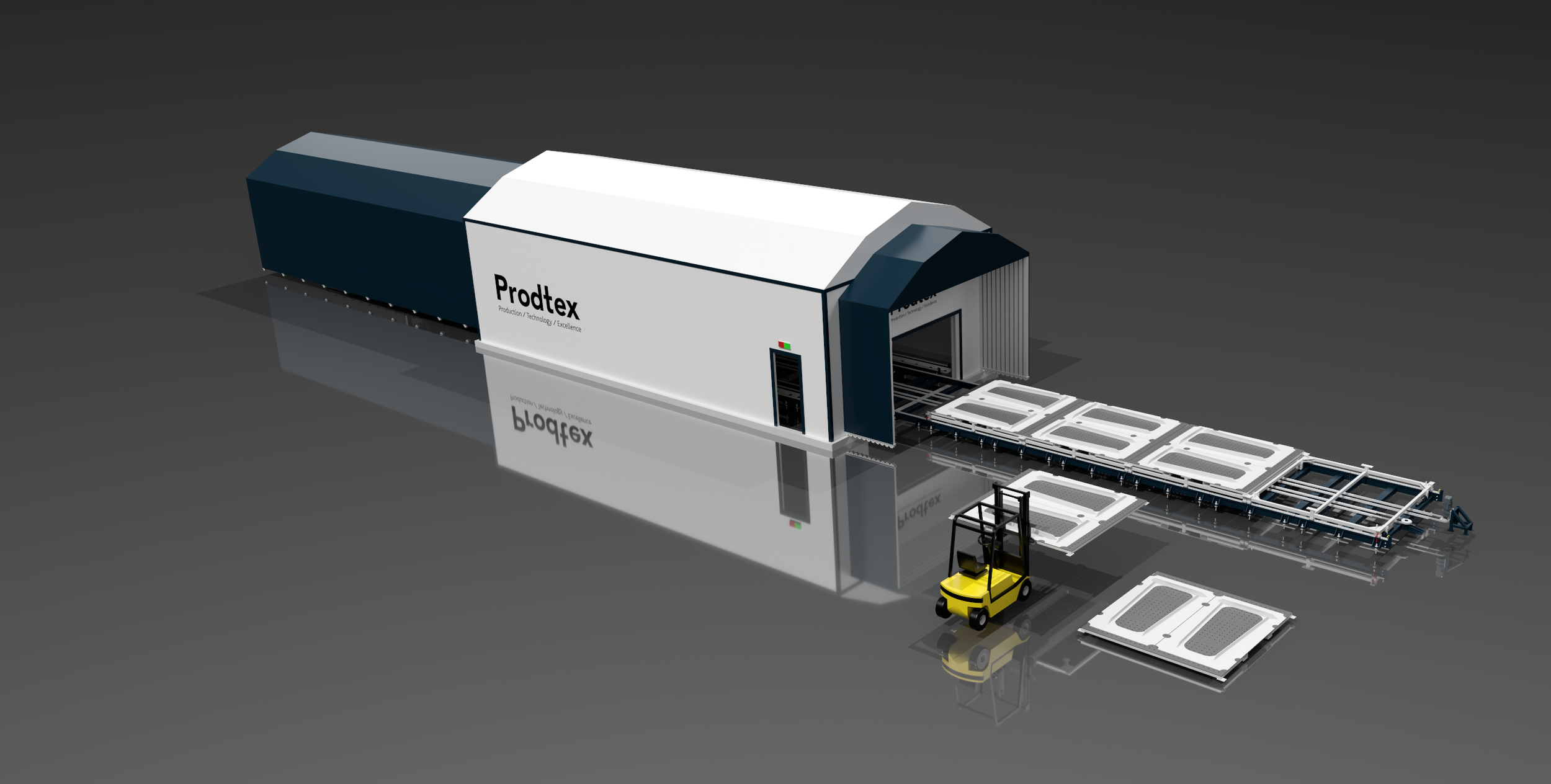

Enclosed Welding Area

For outdoor operations, welding is performed inside a protective enclosure that shields against wind, rain, and other elements. This setup ensures stable conditions, safety, and high-quality welds. Additional weather protection can be provided by adding retractable tents at each end.

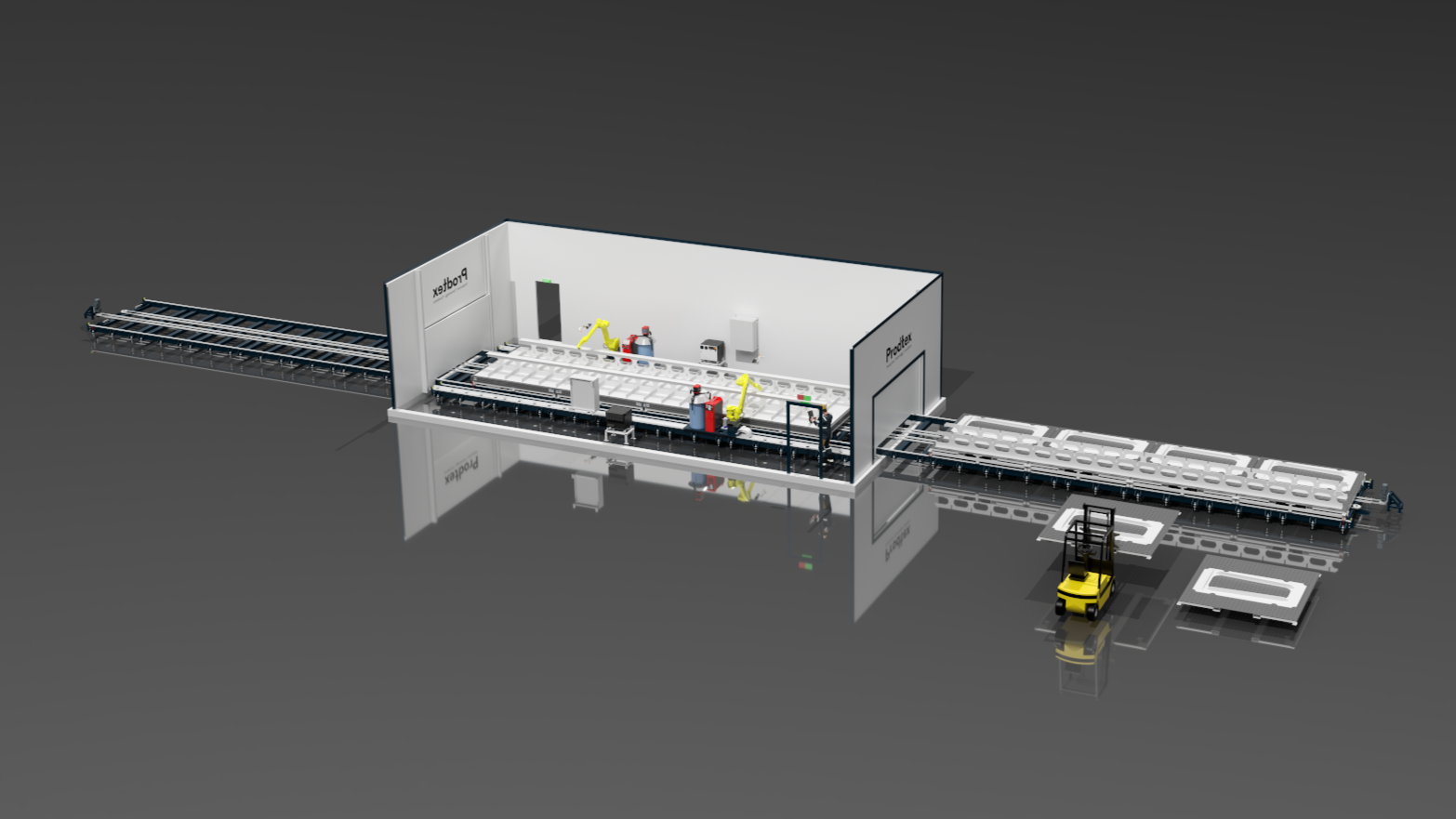

Open-Line Configuration for Indoor Use

When installed inside workshop facilities, the welding line can be delivered without weather protection. This open configuration reduces footprint and simplifies integration into existing production environments, while maintaining full functionality and safety features.