Laser Metal Deposition

Prodtex Norge has hands-on experience with Laser Metal Deposition, a cutting-edge technique for adding material to metal components. With dedicated equipment available, we offer customers the opportunity to test and develop LMD applications on their own products.

Laser metal deposition is a generative manufacturing method for metals, usually abbreviated to LMD. It can also be referred to as direct metal deposition (DMD) or direct energy deposition (DED).

Unlike conventional 3D printing, LMD uses a high-energy laser beam to create a molten pool on the component surface. Metal powder is then precisely delivered into this pool through a nozzle, enabling controlled material build-up. A wide range of metal powders is available, allowing customization for specific applications and performance requirements.

The true strength of LMD lies in its versatility. In addition to printing entire components from scratch, LMD excels in applications such as:

⦁ Repairing high-value parts to extend service life

⦁ Applying protective coatings for corrosion resistance

⦁ Adding functional features to existing components

This technology opens up new possibilities for cost-efficient, sustainable manufacturing, where precision and flexibility are key.

Additive Manufacturing

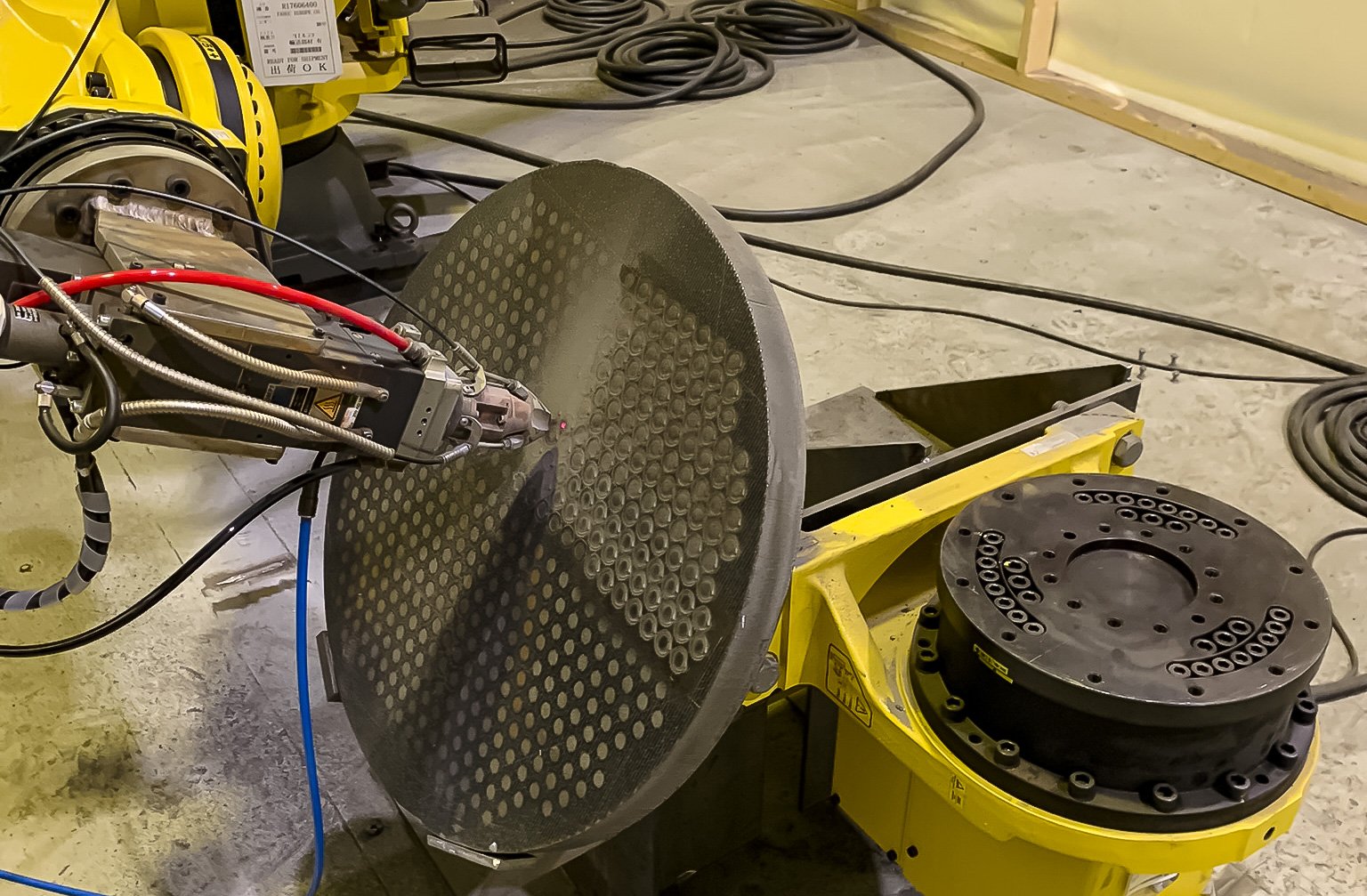

Additive manufacturing is increasingly used to produce components from the ground up. However, a major limitation of traditional 3D printers is the restricted size of the build chamber. This constraint can be overcome by using robot-mounted Laser Metal Deposition (LMD), which also allows for multi-directional material application—not just vertical layering.

With digital twin and simulation tools, key parameters such as material type, layer structure, weight, production time, and cost can be evaluated before manufacturing begins. The technology also supports multi-material builds, enabling cost-effective combinations—such as a mild carbon steel core with a stainless steel surface—for optimized performance and price.

Coating & Surfacing

Surface treatment of steel is often essential to prevent long-term degradation. While stainless and weathering steel offer improved resistance, they come at a higher cost compared to mild steel. Traditional methods like thermal spraying and painting are effective but involve time-consuming processes and health risks.

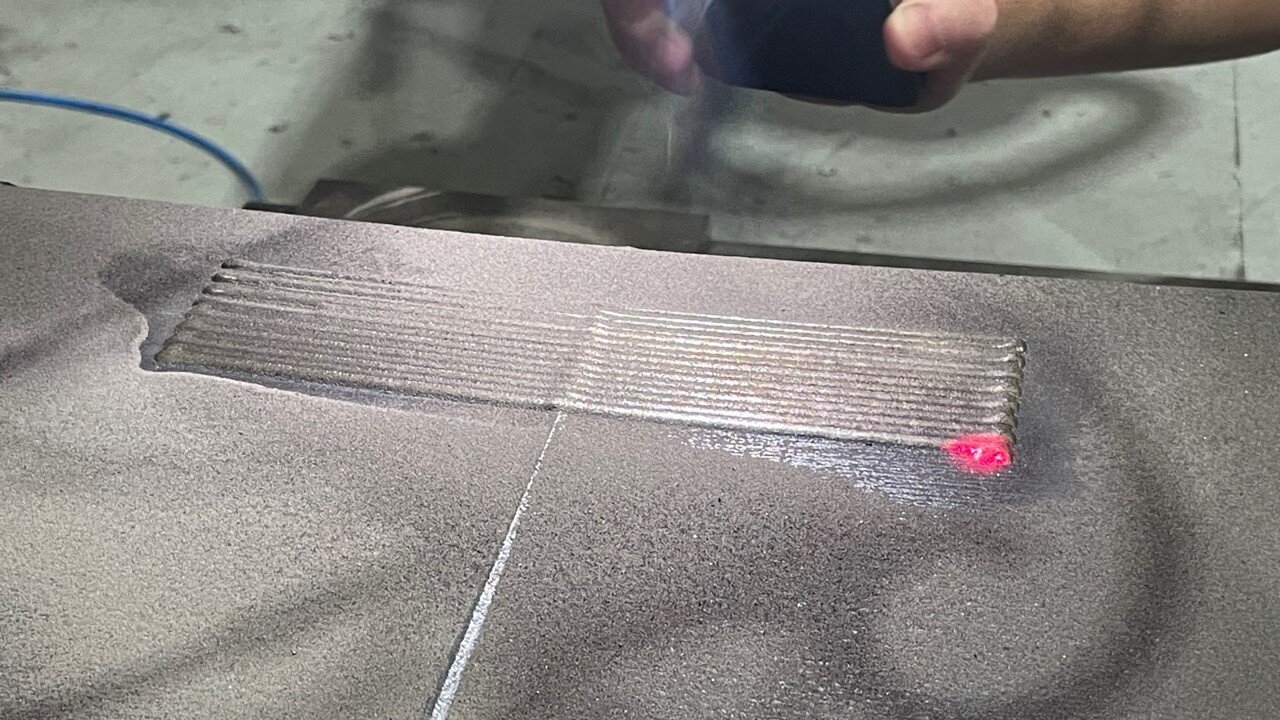

Laser powder cladding—also known as laser surfacing—is a modern alternative. Using a laser beam to create a molten pool on the steel surface, corrosion-resistant metal powder is applied to form a metallurgically bonded layer. The result is a pore- and crack-free coating with excellent durability.

Key advantages:

• Automated, robotic process

• Low exposure time and depth of laser (HAZ)

⦁ Higher durability than thermal spray coatings

⦁ Little to no post-processing required

⦁ Wide selection of powder materials available