Laser & Welding Technology

Prodtex Norge provides advanced manufacturing technologies for welding, additive manufacturing, and surface treatment. Our core competencies include laser and laser-hybrid welding, conventional MIG/TIG welding, laser metal deposition (LMD), and automated laser cleaning systems.

While our laser-based solutions are engineered to deliver superior welding speed, high precision, and minimal heat input — our MIG and TIG welding capabilities offer robust, time-tested methods ideal for demanding structural steel applications. This combination allows Prodtex Norge to provide tailored solutions across a wide range of industrial needs, from high-efficiency automated systems to flexible, manual or semi-automated fabrication processes.

Laser Welding

Laser Welding: Pure laser welding relies solely on a focused laser beam to fuse materials, offering unmatched precision and minimal heat input. The result is a narrow weld seam with a very small heat-affected zone (HAZ), which helps preserve the mechanical properties of the base material and reduces post-processing needs.

Laser-Hybrid Welding: Combines the precision of laser welding with the robustness of arc welding. By merging these technologies, the process benefits from deep penetration and high welding speed from the laser, while the arc provides additional filler material and improved gap-bridging capability.

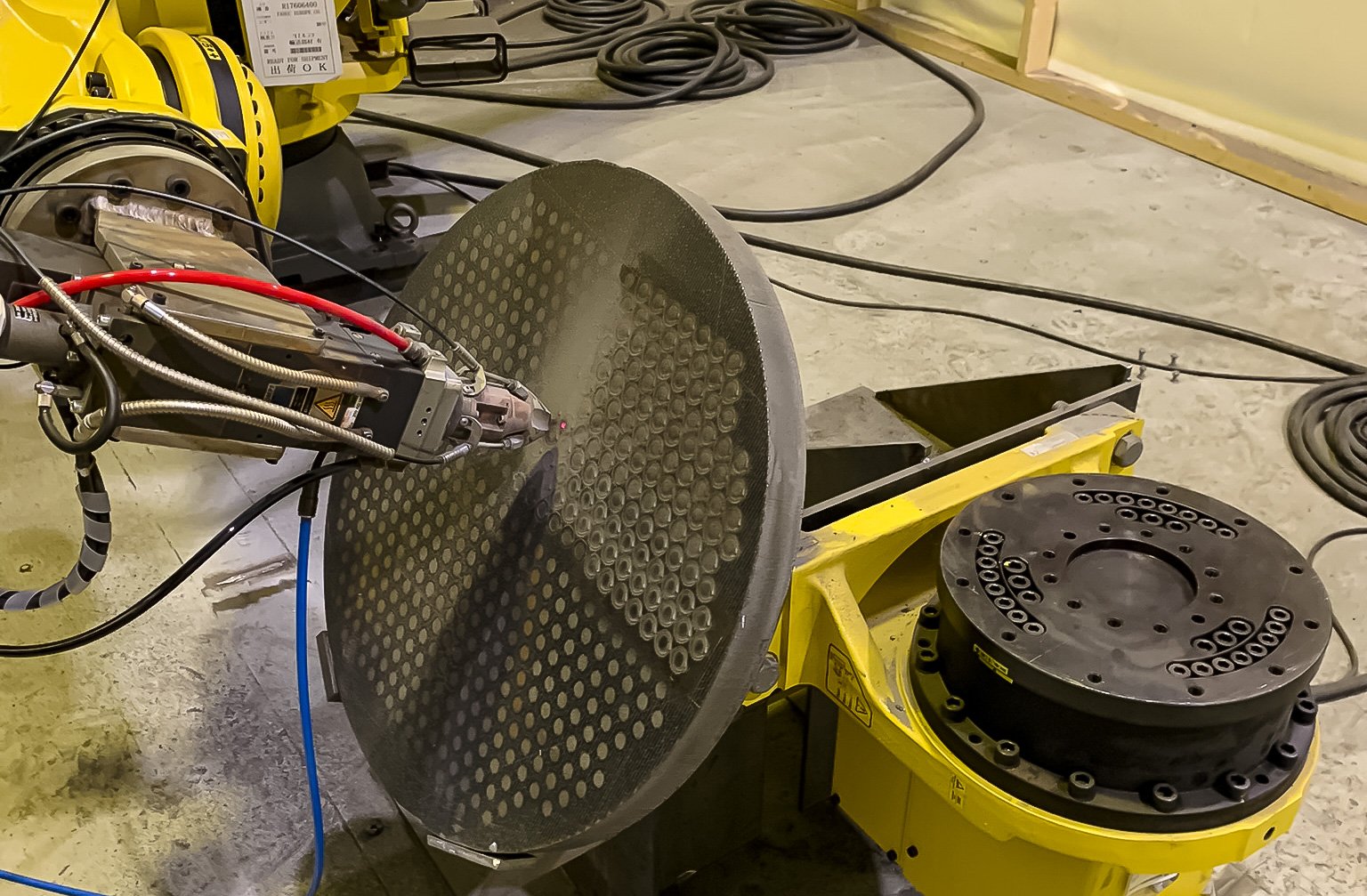

Conventional Welding: By automating traditional welding techniques (like MIG and TIG), higher and more consistent weld quality, improved repeatability, and reduced production time can be achieved.

Coating & Surfacing: Laser powder cladding is a modern alternative to traditional surface treatment, where the laser beam creates a molten pool on the steel surface and the desired metal powder is applied.

Additive Manufacturing: Ideal for repair, reinforcement, and additive manufacturing, LMD technology overcomes the size limitations of conventional 3D printing—enabling precise metal deposition directly onto new or existing components.

Laser Surface Treatment: a precise and contact-free method for removing unwanted surface layers such as rust, paint, oil, oxides, and other contaminants from metal surfaces.

The process is handled by robots to ensure high efficiency and continuity. Handheld laser cleaning equipment is available for treatment of smaller and medium sized products.