Design & Engineering

We perform and offer engineering services in all kinds of projects. Both complex and simple challenges are solved by a multidisciplinary team of experienced engineers. We offer product and specification development, structural analysis, operational simulations, manufacturing documentation and planning, and more.

Our large network of quality suppliers always ensures that the components offered is the reliable choice.

Engineering

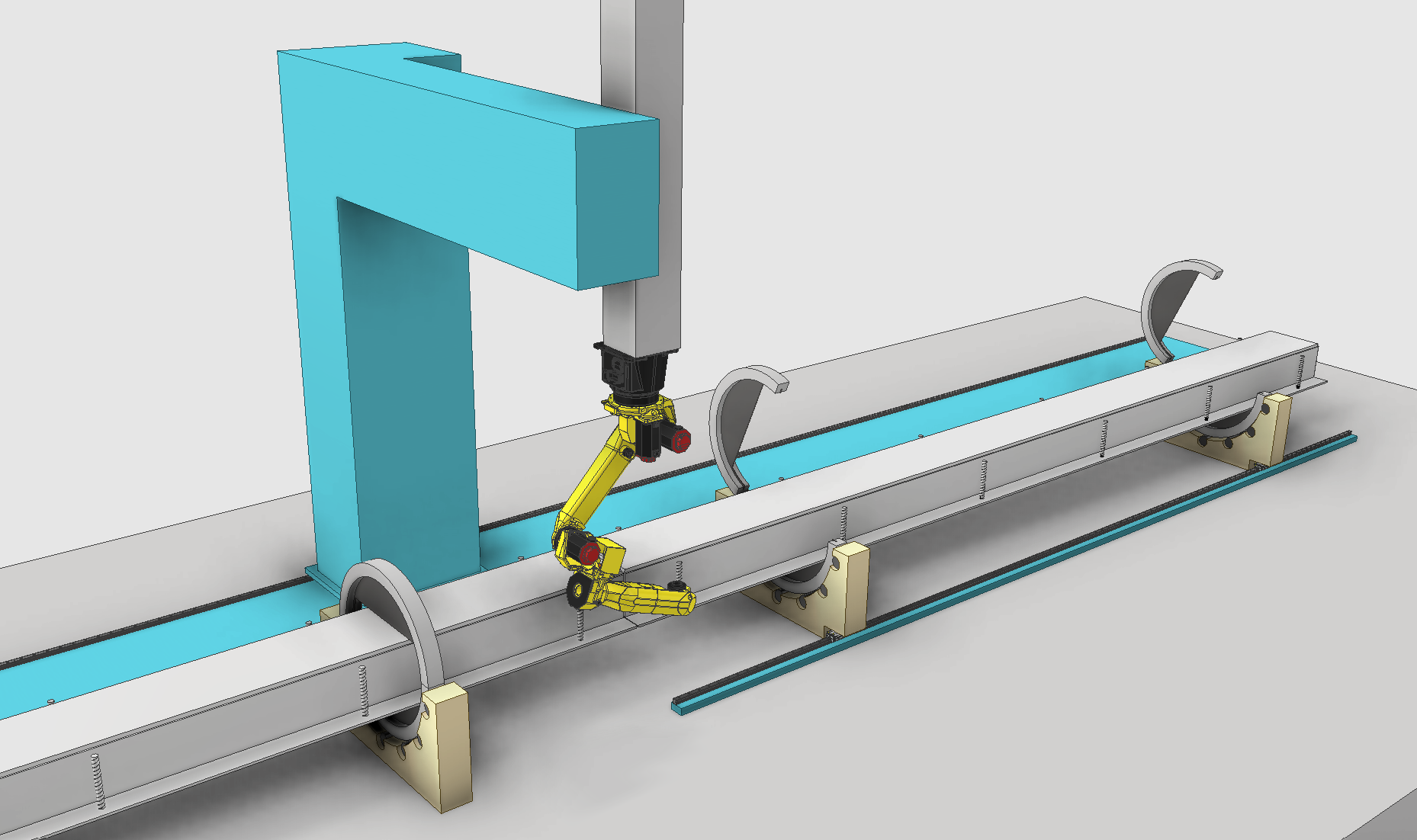

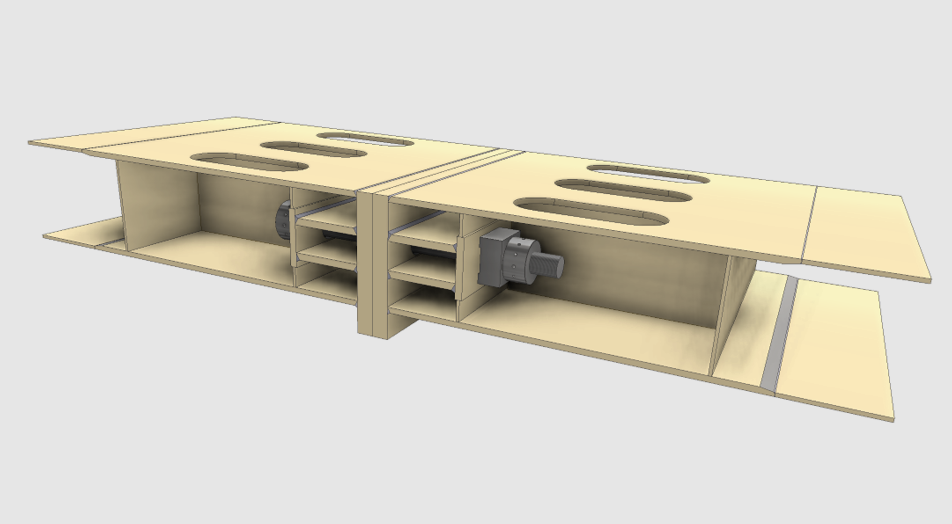

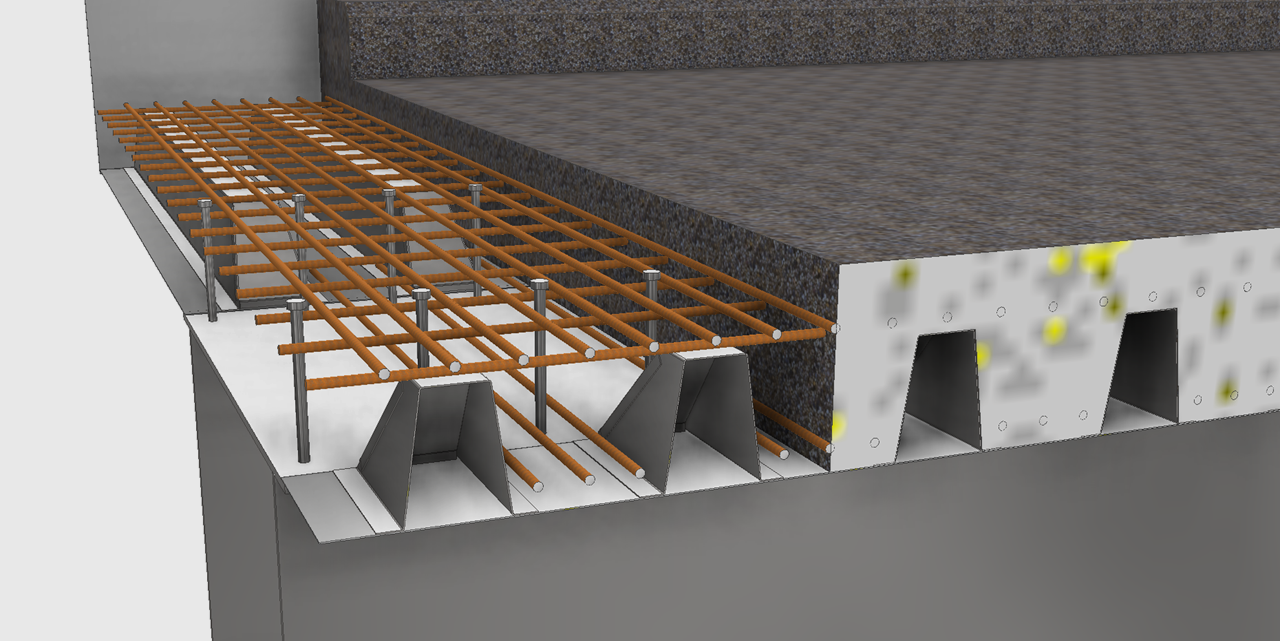

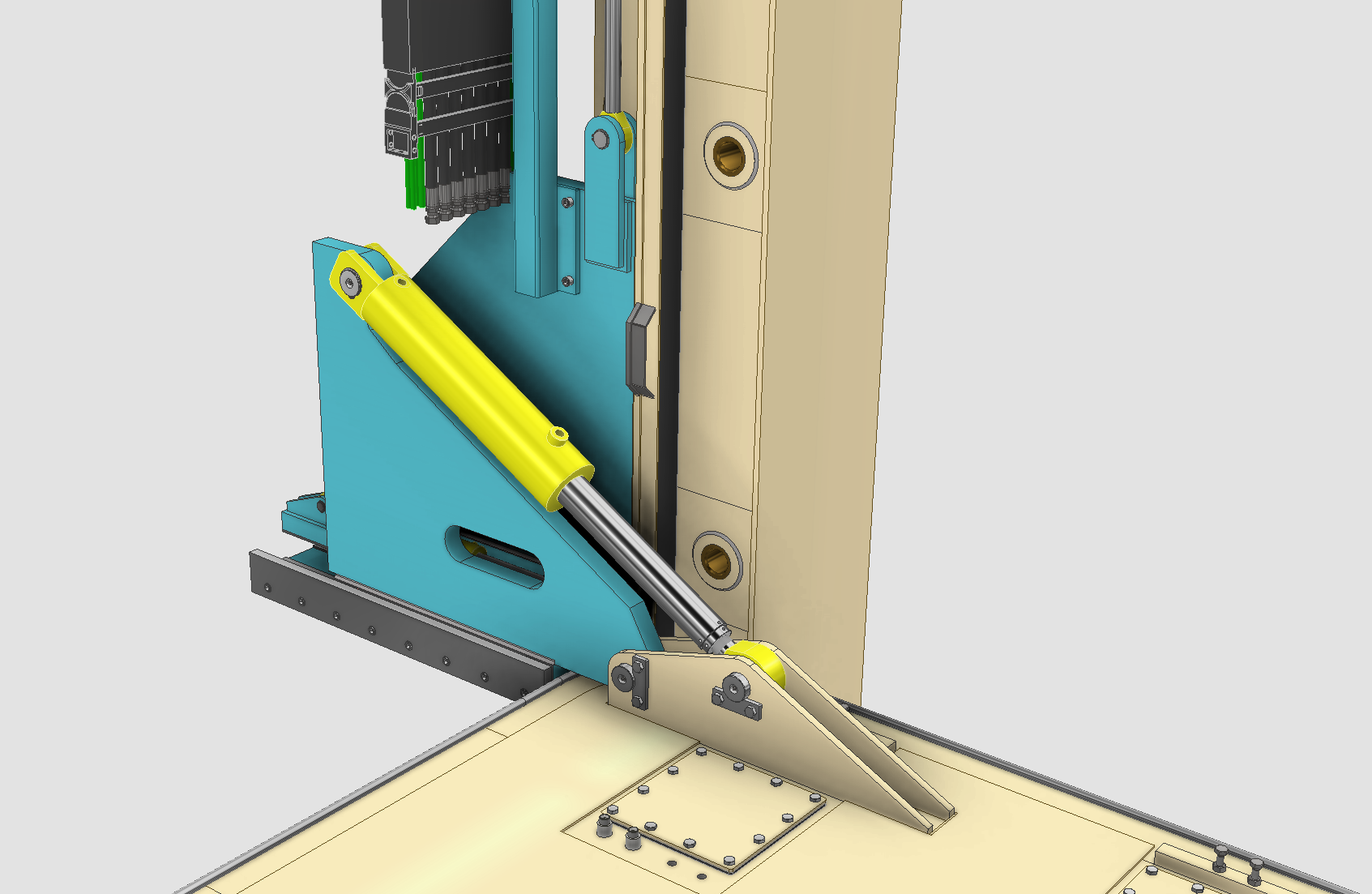

Modern engineering tools enables new and efficient design and engineering processes. Where the industry up until today have been depending on paper documentation for production, modern production equipment allows usage of digital production data.

We can deliver production documentation based on the customers needs, both conventional and modern formats. For internally developed solutions we already deliver complete paperless production documentation packages.

We can offer the following engineering services:

Engineering management

Mechanical engineering

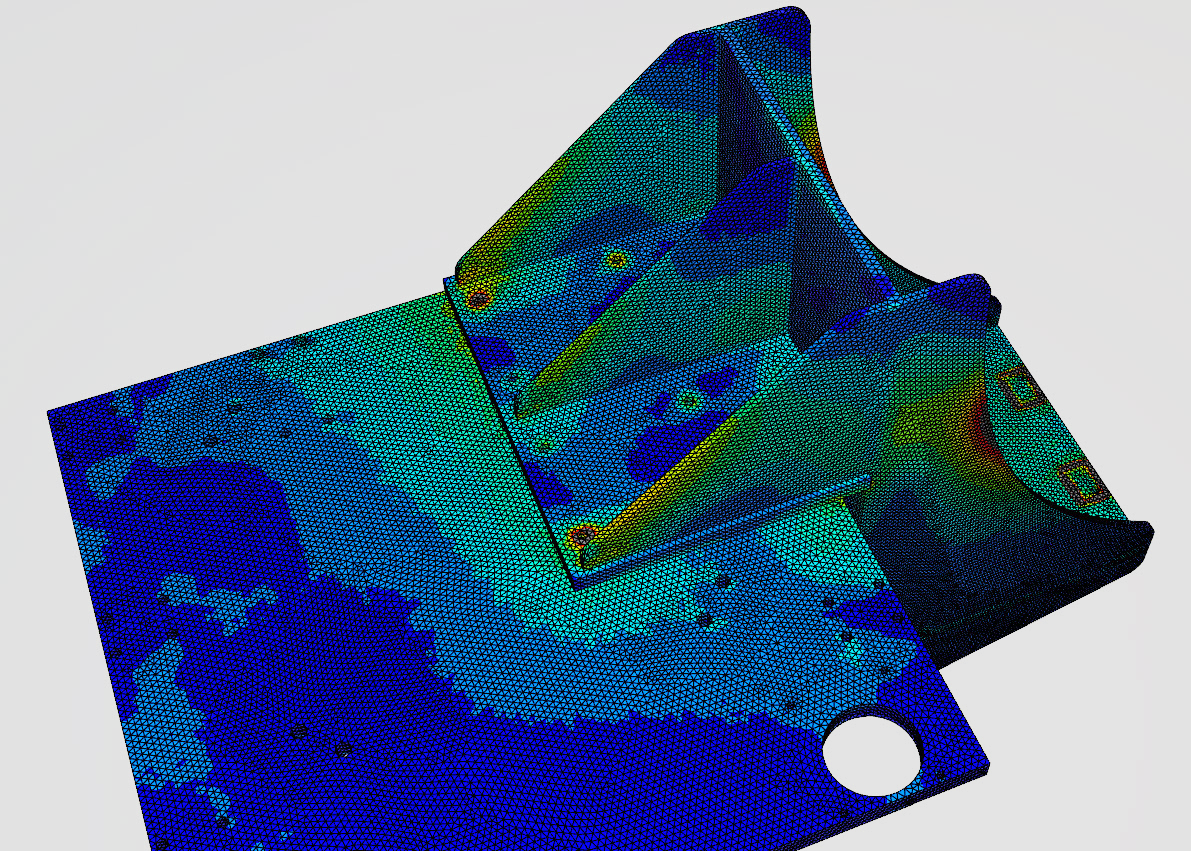

FEM analysis

Automation engineering

Safety engineering

Support long lead procurement

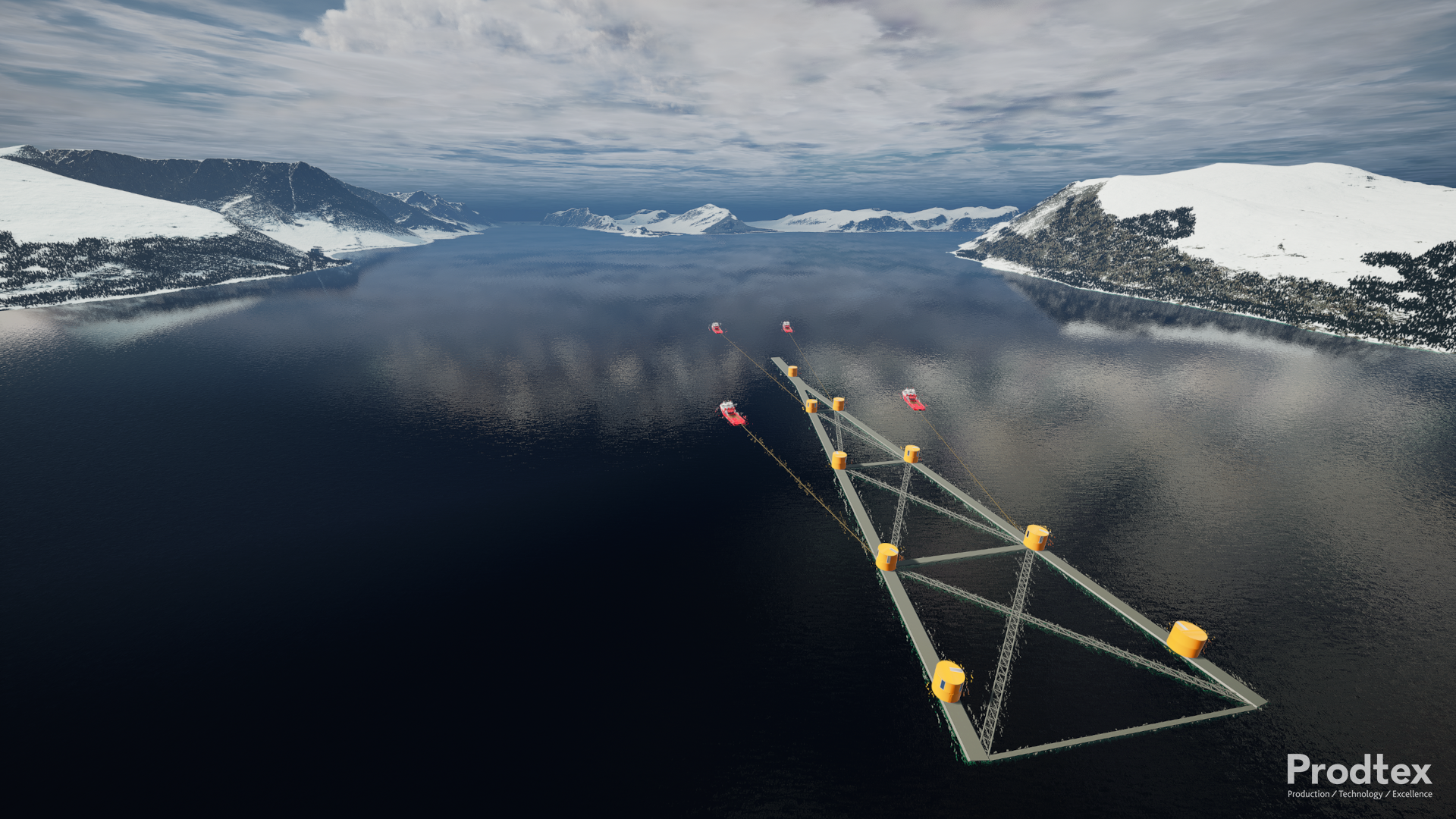

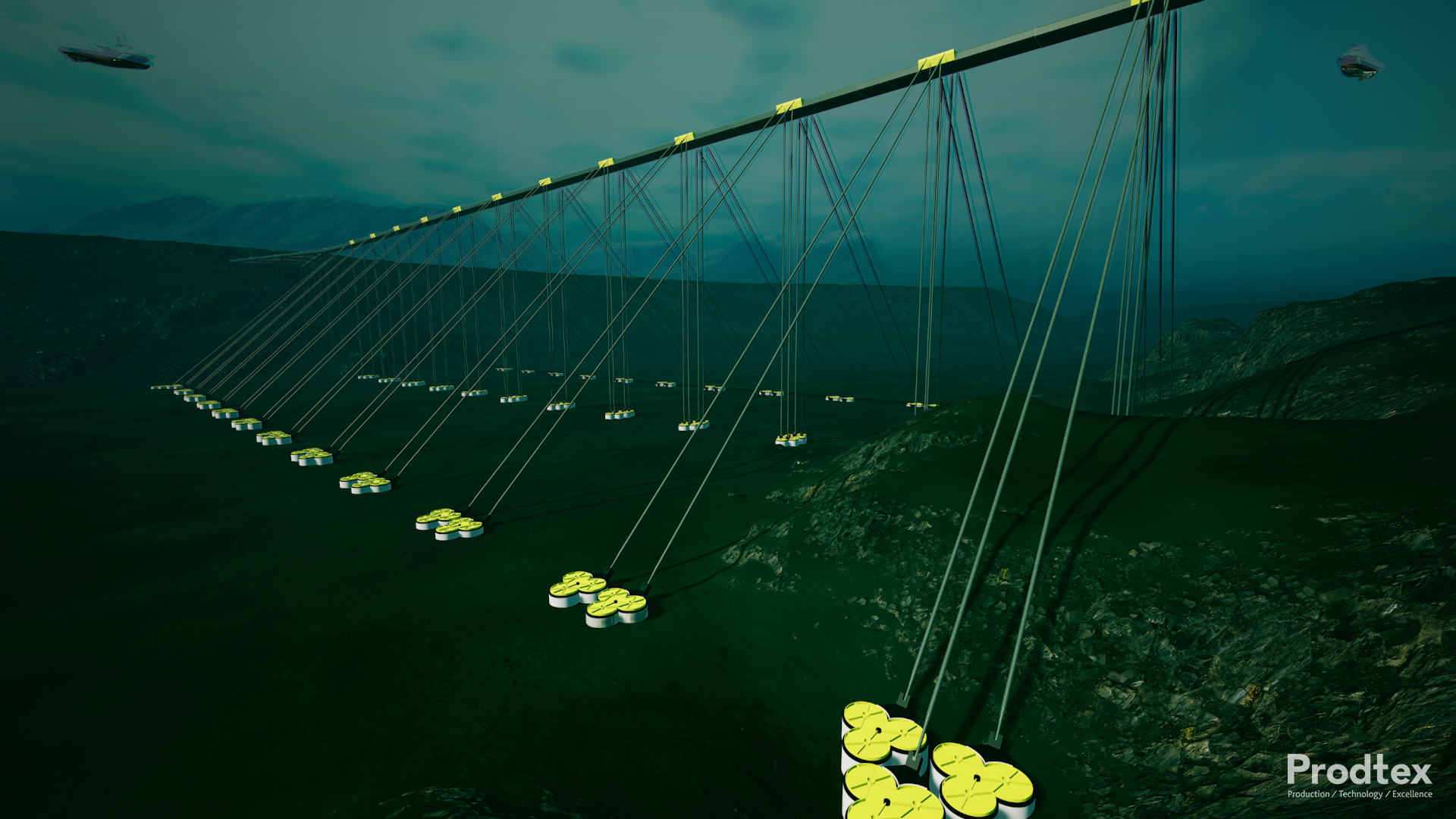

Naval architecture

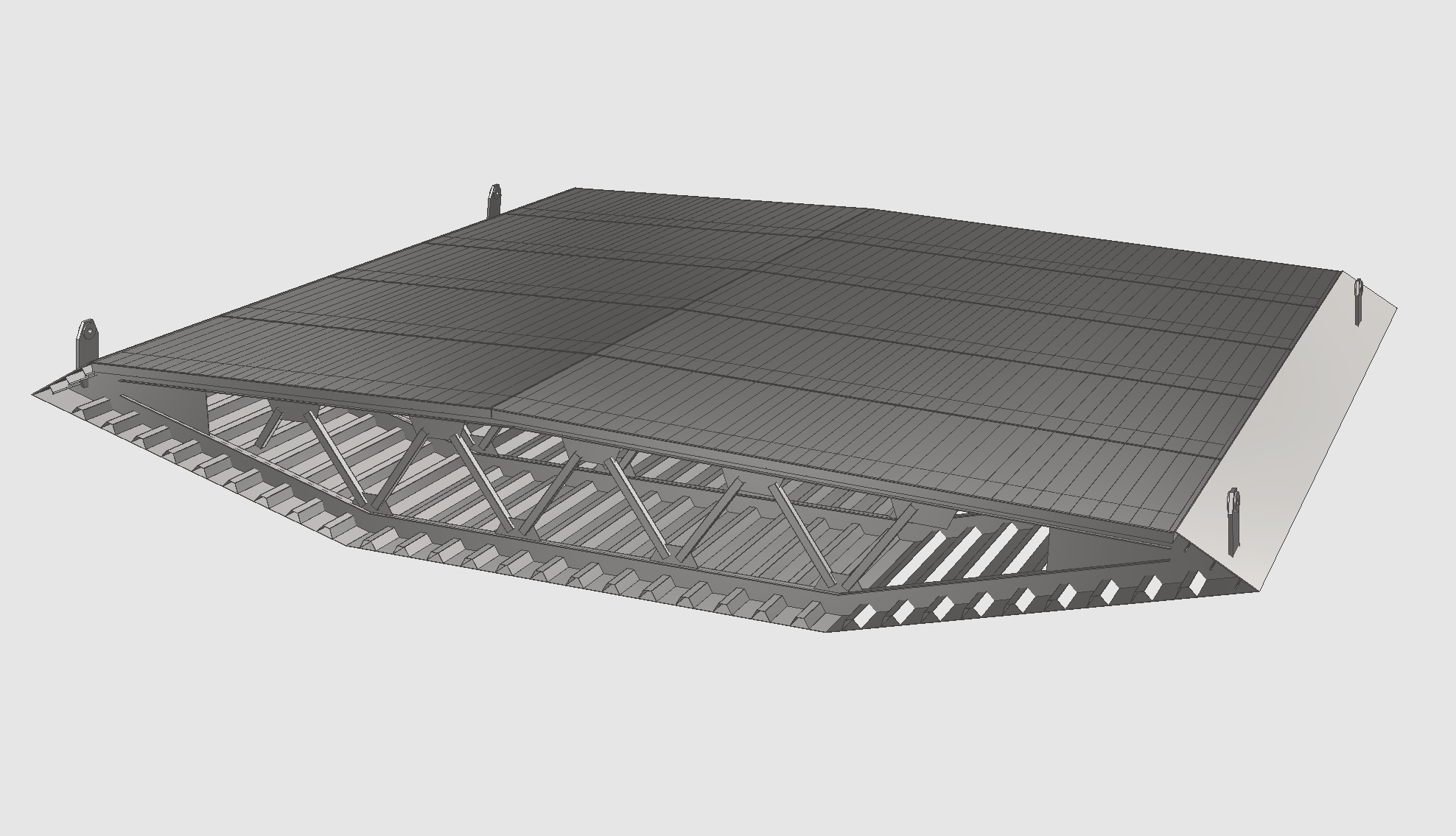

Concept Design

The work leading to a good design solution starts with analysing and understanding our customers business model and strategic goals. Furthermore, we acknowledge the importance of fully comprehend the current production process. This is accomplished by utilizing the customer’s process knowledge, so that we can propose the best suited process design solution.

Our interdisciplinary team with wide industrial experience, can lead and/or provide support in the design process and define requirement specification and goals alongside the customer.

We recommend customers to introduce a digital twin already in the conceptual phase, and continuously develop the twin through the process lifecycle. In the conceptual phase, a simplified 3D model of the desired solution is defined. The 3D model is working as a “data carrier”, in which we assign basic physical behavior and kinematics. By utilizing this methodology, initial behavior simulation can be defined and studied. This enables early identification of possible design flaws and thus prevent large rework operations in the detail engineering phase.