Digital Services

GJENNOMGÅ TEKST UNDER

At Prodtex, we utilize digital twin technology and Dassault’s powerful software platform to streamline and automate modern production processes. By simulating and programming in a virtual environment, we ensure precision, efficiency, and full digital traceability. Our expertise in the 3DEXPERIENCE platform, along with custom software development, enables us to deliver scalable solutions tailored to both small and large industrial needs.

Digital Twin

Software

Digital twin

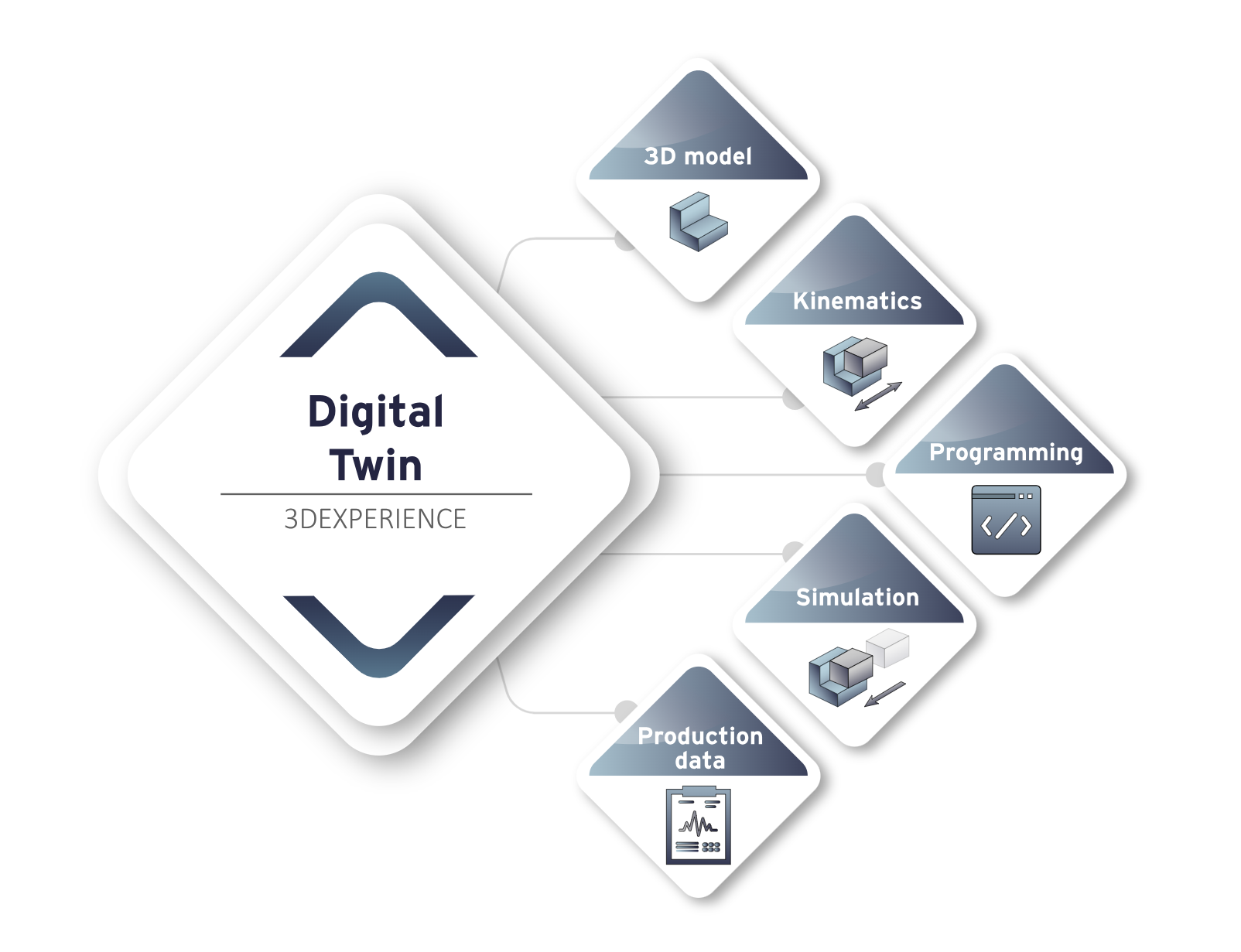

Digital continuity is an important topic for us; thus, our methodology revolves around the usage of a digital twin. A 3D model of the physical assets is the base component of the twin and is working as a “data carrier” containing the necessary metadata and information. Physical behavior of the different components are analysed through suppliers data sheets and applied to the corresponding twin model. Kinematics of moving components are also defined, including inverse kinematics of robot manipulators. With the necessary mechanisms and kinematics in place, programming of the automated solutions in the twin is performed.

Offline Programming

Programming in the digital twin is often referred to as offline programming. A completed program may be ran as a simulation on a computer or on the physical twin. The ability to simulate the process is an excellent method to visualize how the physical objects will move and interact with each other, as well as detecting clashes and other irregularities in the program before it happens in the physical world.

Real-time Data Capture

In a production setting, sensor and process data are collected and stored in the digital twin. This data can be used to analyze different parameters of the production execution, and thus improving efficiency.

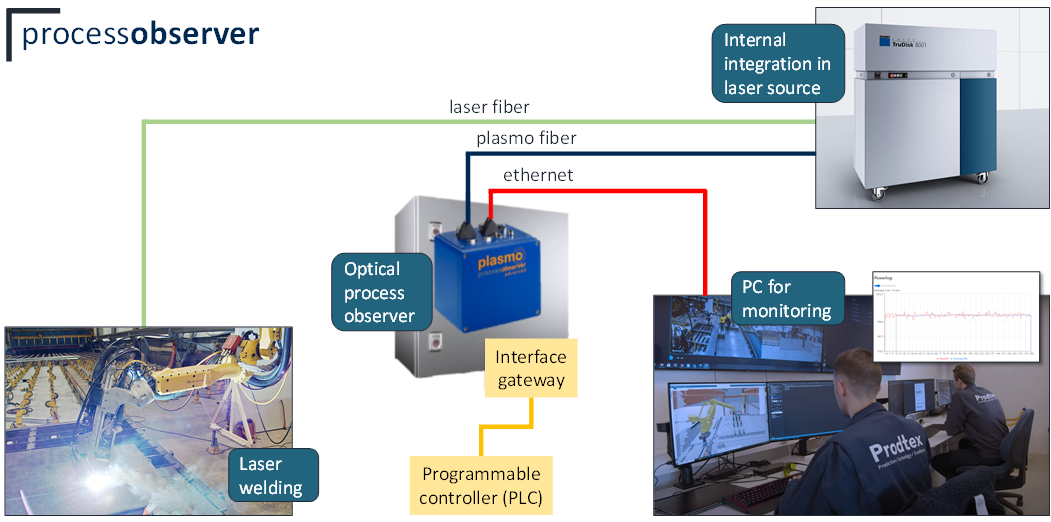

Welding data is the main process that we capture data on in our own facility. Especially the laser welding equipment is monitored closely through an optical process observer, which enables us to locate errors in a weld in real-time during welding. This makes it possible to stop the welding process if something is out of the ordinary, and also help the operators to locate the errors to correct them.

Software

Modern production methods require modern software solutions. One of the key components and success factors in Prodtex is the 3DEXPERIENCE platform. In addition to utilizing the platform in-house, Prodtex is also a reseller of 3DEXPERIENCE through a partnership with Dassault Systèmes. Development of add-ons, support and training of personnel can be offered on-demand.

3DEXPERIENCE

The 3DEXPERIENCE Platform is a Business Experience Platform created by Dassault Systèmes. It provides software solutions for every department in your company - from marketing, sales to engineering & production. With a single, easy-to-use interface, it powers industry solution experiences, based on 3D design, analysis, simulation and intelligence software in a collaborative interactive environment.

Dassault Systèmes offers industry-leading applications delivered on the 3DEXPERIENCE platform: Design & Engineering, Manufacturing & Production, Simulation, Governance & Lifecycle, 3D Design Experience for Professionals, as well as a broad catalog of services.

The platform are available both as an on-premise solution and on the cloud. The cloud is transforming the way companies do business, and 3DEXPERIENCE on the Cloud is no exception. Instant deployment, automatic updates and built-in security systems lowers the workload on IT administration significantly, compared to on-site servers and on-premise solutions.

CATIA is the world’s leading engineering and design software for product 3D CAD design. It addresses all manufacturing organizations, from OEMs through their supply chains, to small independent producers.

DELMIA helps industries and service providers connect the virtual and real worlds through the 3DEXPERIENCE Platform. This allows them to collaborate, model, optimize and perform their operations.

SIMULIA delivers realistic simulation applications that enable users to accelerate the process of evaluating the performance, reliability and safety of materials and products before committing to physical prototypes.

ENOVIA powered by the 3DEXPERIENCE platform, enables stakeholders across the enterprise to contribute in innovation, with a broad portfolio of technical and business applications.

Software Development

Digitization of the workplace is more important than ever before. Automation of tedious and cumbersome tasks are necessary to give employees more meaningful and value-adding tasks, as well as achieving higher profitability for the company. We develop customized applications to automate tasks and processes in several disciplines, for both small and large companies.

Our applications are based on modern frameworks and are developed as cross platform web applications or basic Windows applications, depending on the customer needs. We use cloud-based databases to store all customer data, to make sure that the data is secure and easily available to all stakeholders.

Development of applications to automate handling and preparation of 3D data for automated production is one of our specialities. This is achieved by creating applications that run on-top of Dassault Systèmes software, combining it with external databases. With this approach, full digital traceability of the production data can be ensured, which makes it easier to handle new and future demands from class societies and authorities.